Galvanic Action - Mismatching of Corrosion Protected Steel Products

February 9, 2022

Generally, galvanic action occurs where different levels of corrosions protection are in contact and the hierarchy of corrosion protection will influence the overall performance. Lower level corrosion protected elements will ‘sacrifice’ themselves ahead of higher protected materials they are in contact with. As a result dissimilar metals (such as Type 316/304 stainless steel and zinc) in contact with each other and located in a corrosive environment will exhibit an increase in the rate of corrosion activity, compared to the rate of corrosion activity that would ordinarily occur for similar protected materials in contact. The increase in the rate of corrosion activity is affected by many factors, such as the specific dissimilar metals and the local environment. BRANZ has investigated galvanic action and more information can be found on their website.

In an effort to better understand the corrosion effect particularly of combining stainless steel fasteners with zinc protected products, Simpson Strong-Tie also conducted a controlled corrosion test in a salt-spray environmental chamber (ASTM B117). The test consisted of a zinc–coated washer and zinc coated and powder-coated post bases assembled with both zinc-coated Titen HDs (the control samples) and with stainless steel Titen HDs (the subject samples). After 1000 hours of salt spray, the corrosion amounts were measured. The results of this test showed that the corrosion rate for these assemblies was not increased when the dissimilar metals of the stainless-steel Titen HD and zinc-coated post base were in direct contact. An important note is that other dissimilar metal assemblies will not perform the same under similar conditions.

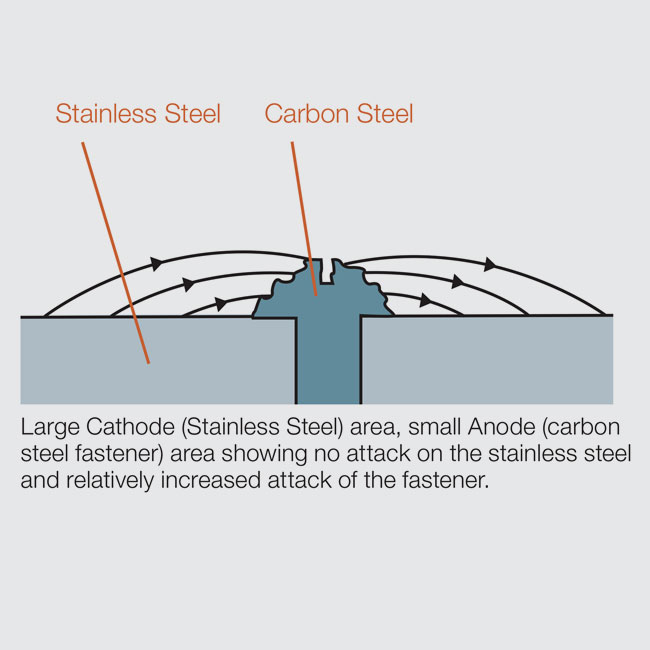

Surface areas of the dissimilar metals contribute significantly to the overall performance, and so using a large zinc protected steel elements with stainless fasteners for example would be expected to perform reasonably well. Whereas a large stainless connector fixed with zinc protected fasteners will result in significantly accelerated corrosion of the fasteners. This is due to the galvanic action by which the zinc on the fasteners will ‘sacrifice’ itself to ‘protect’ the surrounding stainless. Because of the small amount of zinc present on the fasteners this would quickly be consumed and the black steel being left to corrode.

It is particularly important therefore to use stainless fasteners with stainless (or potentially zinc protected) connectors, and zinc protected fasteners avoided with stainless connectors unless a proper study to understand the effects has been undertaken.

Structural Connections

Unmatched Quality from the Truss to the Foundation

With nearly 60 years of field and R&D experience, Simpson Strong-Tie® timber connectors are manufactured to the industry's highest standards. From framing angles to straps to heavy-duty joist hangers, we offer the most diverse product line so that you have the right product for the job.

Simpson Strong-Tie® connectors offer unmatched quality with laboratory and field testing, and are backed by our uncompromising commitment to customer service. As the company that built the connector industry, you can count on Simpson Strong-Tie® to work closely with builders, engineers and building officials to deliver innovative, building code-compliant solutions to help build safer, stronger structures economically. Download the Timber Connectors NZS 3604 Catalogue.

Timber Connectors

From testing to service to availability, everything we do is engineered to ensure your project's success. With every product, you know you are getting the quality, value, service and on-time delivery that we have built our reputation on for the past 60 years.

From straps and ties to joist hangers and much more, Simpson Strong-Tie® structural connectors increase the strength and safety of timber-frame structures. Each connector is unique to Simpson Strong-Tie and is designed for specific applications without the need to adapt metal plating to suit a connection. Download the Engineered Structural Connectoions flyer.

Steel Frame Connectors

From fully tested and engineered connectors and clips Simpson Strong-Tie® provides comprehensive structural solutions for cold-formed steel construction. From steel-to-steel connections to full-scale lateral solutions and curtain wall connectors, we remain committed to developing new technology that helps to advance the cold-formed steel industry.

Find out how Simpson Strong-Tie timber connectors can help you build the right way every day. Download the Cold-Fromed Steel Construction Connectors Catalogue.