Solutions

Anchoring Systems

One of the core values at Simpson Strong-Tie® is to help you succeed by providing innovative products, full-service engineering and field support, product testing and training, and on-time product delivery. We have become a trusted manufacturer of innovative anchor systems solutions for infrastructure, commercial, industrial and residential projects. We offer a full array of mechanical and chemical anchors and tools for concrete and masonry applications. Our anchor systems, like all of our others, have passed the high performance and quality standards that are expected of Simpson Strong-Tie® – and include the trusted level of service you've come to rely on.

Chemical Anchors

From rebar doweling on a high-traffic infrastructure retrofit project to do-it-yourself projects, Simpson Strong-Tie® offers a wide variety of adhesive anchoring products to meet virtually any need.

From rebar doweling on a high-traffic infrastructure retrofit project to do-it-yourself projects, Simpson Strong-Tie® offers a wide variety of adhesive anchoring products to meet virtually any need.

Our strong, versatile epoxy-based adhesives are ideal for anchoring threaded rod, rebar and smooth dowels in an assortment of base materials. And our acrylic formulations deliver consistent performance for high-strength anchor grouting in a wide range of weather conditions — curing fast even in water-saturated concrete. Learn more

Mechanical Anchors

From complex infrastructure projects to do-it-yourself ventures, Simpson Strong-Tie® offers a variety of screw style anchoring products to meet virtually any need.

From complex infrastructure projects to do-it-yourself ventures, Simpson Strong-Tie® offers a variety of screw style anchoring products to meet virtually any need.

Our mechanical anchors are designed to install easily and securely into a variety of base materials — from concrete and brick to masonry. They offer optimal performance even in the most demanding structural applications. For applications where there is a risk of concrete cracking, specific anchors have been designed and tested to offer reliability under these conditions. Learn more

Fastening Systems

Driven to Exceed Expectations

In the fastener marketplace, Simpson Strong-Tie stands apart from the rest. Quality and reliability is our top priority. We have metallurgists, materials engineers, and structural engineers to create the best possible fasteners. Each production run goes through rigorous testing to ensure our products can handle higher loads, resist corrosion, and make installation more efficient.

Hand Drive Fasteners

Sometimes you need a fastener that does more. Maybe you're looking for higher loads or additional corrosion resistance, or perhaps an installation method that saves time. Whatever it is, you are no longer looking for just a fastener; you are looking for a solution. Our series of Strong-Drive®, Deck Drive™, Quik Drive® and Stainless-Steel fasteners offer quality and reliability for a variety of fastening applications. Learn More

Quik Drive® Auto-Feed Screw Driving Systems

Collated-screw fastening tools are replacing traditional nail guns for their speed, reliability and power. Quik Drive® auto-feed screw driving systems are ideal for a broad range of fastening applications because they feature quick-loading screw strips, precise countersink adjustment, and a patented auto-advance mechanism. You can improve the quality and durability of your work while reducing time and money spent on jobsites every day. Learn More

CCN64 Collated Connector Nailer

The CCN64 Collated Connector Nailer helps to ensure the correct installation of connectors through its unique design and is considerably faster than traditional hand nailing. The CCN64 has been designed so that connector nails protrude from the tip of the tool. This allows the user to easily locate the tip of the nail into the connector hole so that the connector will not be damaged. The nails are hammered into the timber via multiple blows which prevents the nail from being overdriven. Learn More

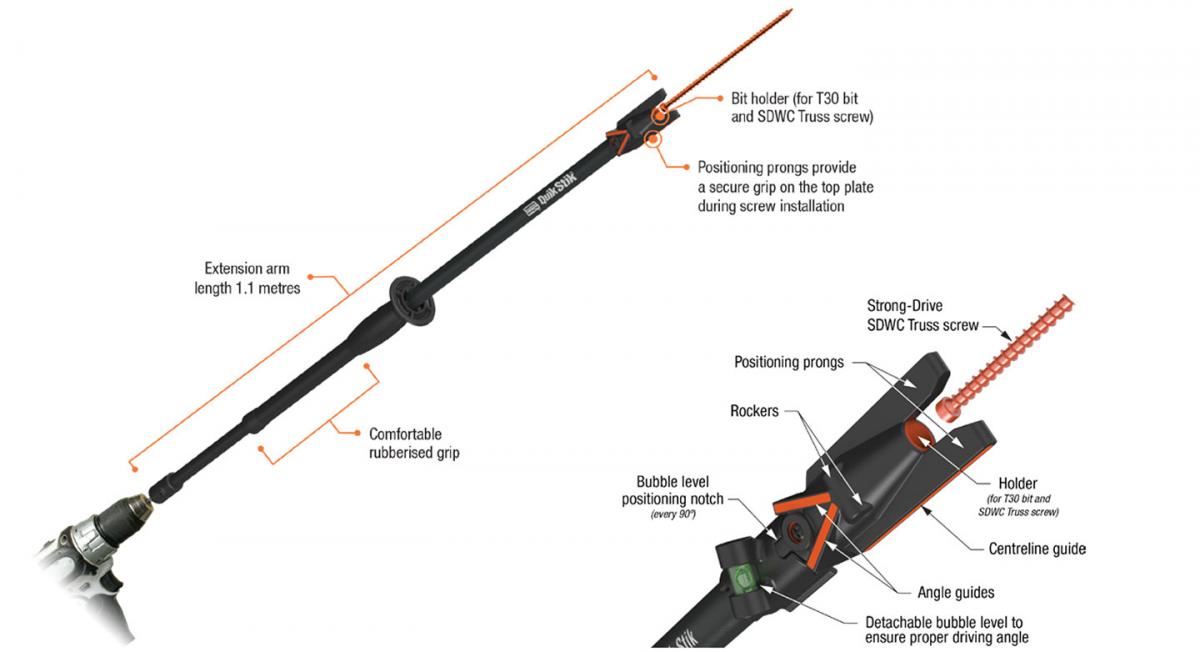

Quik Stik Rafter and Truss Fastening Systems

Introducing the new standard for overhead assembly installations of rafter and truss connections. The Simpson Strong-Tie® Quik Stik installation tool provides contractors with a versatile solution that makes fastening rafter and truss connections fast, safe and easy. Quik Stik and Strong-Drive SDWC Truss screws are designed to work together for a safe, reliable solution.

- Fast installation: Drive screws overhead from a standing position with no ladders

- Safe on the jobsite: Designed for use inside the structure — no need to work outside the building

- Easy to operate — less-experienced users can work quickly and efficiently

- Precise: Bright orange guidelines facilitate proper alignment for each of the approved installations

- Special purpose: Designed specifically for use with the Strong-Drive® SDWC Truss screw for rafter/truss connections

Learn more about Quik Stik™ Rafter and Truss Fastening Systems.

Quik Drive Auto-Feed Screw Driving Systems

Designed to build structures more efficiently

Simpson Strong-Tie® helps people build safer, stronger structures. We do this by designing, engineering and manufacturing productivity solutions that save time, reduce cost and are more ergonomic — allowing our customers to be more productive and cost-efficient with less fatigue.

For high-volume, repetitive fastening, Quik Drive® auto-feed screw driving systems are designed to save time and money.

Quik Drive® Auto-Feed Screw Systems increase productivity while providing superior fastener performance

When it comes to choosing fasteners, the superior holding power of screws over nails is obvious, but the time-saving advantage of driving nails has always tipped the balance in their favour – until you use the Quik Drive® auto-feed screw driving system!

Collated-screw fastening tools are replacing traditional nail guns for their speed, reliability and power. Quik Drive® auto-feed screw driving systems are ideal for a broad range of fastening applications because they feature quick-loading screw strips, precise countersink adjustment, and a patented auto-advance mechanism. You can improve the quality and durability of your work while reducing time and money spent on jobsites every day.

- Subflooring

- Decks/Docks

- Plasterboards

- Fiber-Cement Cladding

- Weatherboard

- Metal Roofing

- Underlayment

- Truck Beds/Trailer Flooring/Landscape

Learn more about

Decking

Your Complete Decking Fastener Solution

Superior performance for decking projects: Deck‑Drive™ screws are designed with the most demanding deck builders in mind. Whether the project calls for timber decking, premium composite, or exotic hardwood, you can trust Deck‑Drive screws to provide you peace of mind.

Available loose for hand-driving, and collated for Quik Drive systems — with free bits in every pack! Download the Deck-Drive™ Premium Fasteners brochure.

Superior Decking Screws by Simpson Strong-Tie

Gone are the days when home owners put up with nails that pull up or squeak on a deck, which has now become a treasured extension of their home.

Our innovation in deck design and construction methodology has not only driven us to release world class products that help the builder create safer and stronger deck structures, but it has also lead us to develop a market leading decking screw range to be enjoyed by both the builder and the home owner alike.

1. DSD HARDWOOD Screw

The DSD hardwood decking screw has been developed to install without the need to pre-drill boards. With toughened 316 stainless steel and coarse threads, it will fasten most species of hardwood. A clean cutting head with a great look, rounds off the Ultimate Decking Screw.

- Low torque design for fast and easy driving.

- Broad head with nibs provides a greater clamping force and allows for a cleaner decorative finish.

- The knurled shank creates a clearance hole in the board.

- For timber and hardwood decking to timber joist.

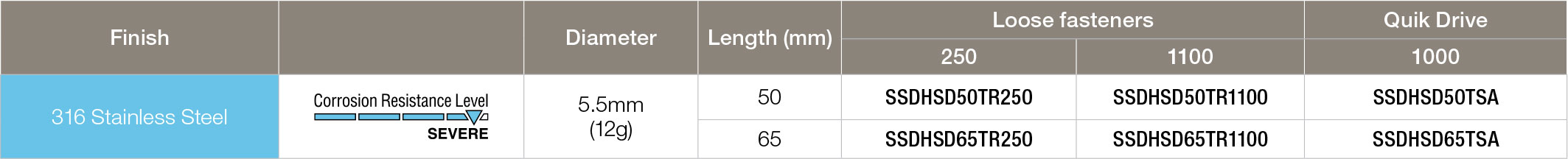

2. DHSD HARDWOOD Screw

The DHSD is specially designed to penetrate the hardest timber decking products with ease. Its unique drill point virtually eliminates countersinking and splitting without pre-drilling. The DHSD is suitable for fixing decking to both hardwood and softwood joist.

The DHSD is specially designed to penetrate the hardest timber decking products with ease. Its unique drill point virtually eliminates countersinking and splitting without pre-drilling. The DHSD is suitable for fixing decking to both hardwood and softwood joist.

- Low torque design for easy driving.

- Raised countersinking head delivers a professional and decorative finish.

- Unique ribbed shank provides greater strength and holding power.

- For timber and hardwood decking to timber joist.

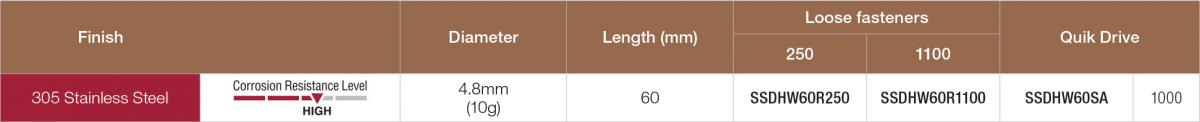

3. DHW HARDWOOD Screw

The DHW is made for easy installation into the hardest timber decking products. Its drill point virtually eliminates splitting without pre-drilling. The wings on the shaft counter‑bore hard material, allowing the head to countersink easily for a clean finish. It is best suited for softwood joists.

The DHW is made for easy installation into the hardest timber decking products. Its drill point virtually eliminates splitting without pre-drilling. The wings on the shaft counter‑bore hard material, allowing the head to countersink easily for a clean finish. It is best suited for softwood joists.

- Compact head for a clean finish.

- The winged design and hardwood drill point virtually eliminates splitting without pre-drilling.

- Class 3 screws are best suited for weather-sheltered decks.

- For fully exposed areas use Stainless Steel.

- For timber and hardwood decking (up to 20 mm thick) to timber joist.

4. DWP SOFTWOOD & HARDWOOD Screw (Loose)

The DWP screw is a powerful fastening solution for decking and general exterior applications where extra corrosion protection is needed. With its specially designed sharp‑point and unique box‑threads, the DWP is ideally suited for the majority of timber used in today’s decking boards.

The DWP screw is a powerful fastening solution for decking and general exterior applications where extra corrosion protection is needed. With its specially designed sharp‑point and unique box‑threads, the DWP is ideally suited for the majority of timber used in today’s decking boards.

- 316 Stainless Steel is suitable for marine environments and has the ductility to allow for movement of timber decking.

- Unique "box" threads with raised-ridge technology greatly reduces driving torque, which allows you to drive more screws on a single battery charge.

- For timber and softwood decking to timber joist.

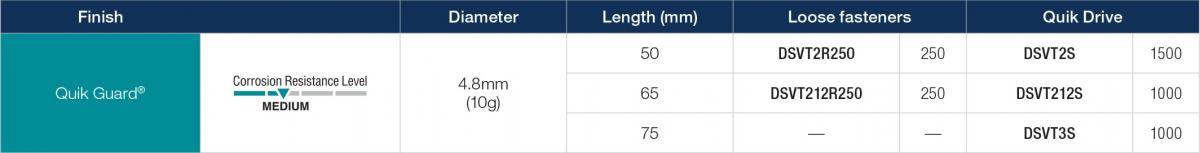

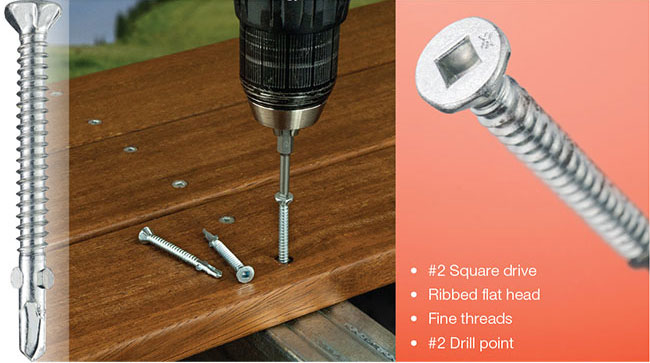

5. DSV SOFTWOOD Screw

The DSV screw is a powerful fastening solution for treated timber decking applications. With its under‑head nibs and fast‑start tip, the DSV is ideally suited to be driven and countersunk into today’s softwood deck boards. The shank is designed to withstand the swelling and shrinkage that is common with fast‑growth timber.

The DSV screw is a powerful fastening solution for treated timber decking applications. With its under‑head nibs and fast‑start tip, the DSV is ideally suited to be driven and countersunk into today’s softwood deck boards. The shank is designed to withstand the swelling and shrinkage that is common with fast‑growth timber.

- Quik Guard® is a Class 3 coating as per AS3566.2

- Fast-start hi-lo tip easily pierces softwood deck boards.

- Low torque design for fast and easy driving.

- Head designed for greater clamping.

- For timber and softwood decking to timber joist.

6. BFHSD BI-METAL Screw - Timber to Steel

The BFHSD is designed to fasten hardwood decking to steel joists without sacrificing performance. This 316 stainless steel bi‑metal screw requires no pre‑drilling, making them easier and faster to install than typical decking screws.

The BFHSD is designed to fasten hardwood decking to steel joists without sacrificing performance. This 316 stainless steel bi‑metal screw requires no pre‑drilling, making them easier and faster to install than typical decking screws.

- 316 Stainless Steel provides superior corrosive protection and is suitable for marine environments.

- Stainless Steel has the ductility to allow for movement of timber decking.

- Zinc coating to prevent dissimilar metal corrosion.

- For timber and decking (up to 25 mm thick) to steel joist (1.2–2.4 mm thick).

Time Saving by Design

Most of the fasteners in this brochure are also available collated for the Quik Drive® System. Quik Drive is the fastest auto-feed screw driving system on the market, ensuring you’ll save maximum time during repetitive fastening applications

Most of the fasteners in this brochure are also available collated for the Quik Drive® System. Quik Drive is the fastest auto-feed screw driving system on the market, ensuring you’ll save maximum time during repetitive fastening applications

Rather than installing individual screws, or other more complicated fastening options, Quik Drive operators can work faster, from an ergonomic standing position, saving your back and knees.

When time is money, Quik Drive is the faster fastener tool.

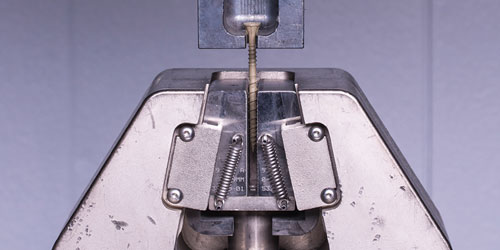

Testing That Goes Above and Beyond

Each production run goes through rigorous testing to ensure our products can handle higher loads, resist corrosion, and make installation more efficient.

Each production run goes through rigorous testing to ensure our products can handle higher loads, resist corrosion, and make installation more efficient.

Driven to Exceed Expectations

In the fastener marketplace, Simpson Strong‑Tie stands apart from the rest. Quality and reliability is our top priority. That's why we hire PhDs, metallurgists, materials engineers, and structural engineers to create the best possible fasteners.

For more information, download the Deck-Drive™ Premium Fasteners brochure.

Structural Connections

Unmatched Quality from the Truss to the Foundation

With nearly 60 years of field and R&D experience, Simpson Strong-Tie® timber connectors are manufactured to the industry's highest standards. From framing angles to straps to heavy-duty joist hangers, we offer the most diverse product line so that you have the right product for the job.

Simpson Strong-Tie® connectors offer unmatched quality with laboratory and field testing, and are backed by our uncompromising commitment to customer service. As the company that built the connector industry, you can count on Simpson Strong-Tie® to work closely with builders, engineers and building officials to deliver innovative, building code-compliant solutions to help build safer, stronger structures economically. Download the Timber Connectors NZS 3604 Catalogue.

Timber Connectors

From testing to service to availability, everything we do is engineered to ensure your project's success. With every product, you know you are getting the quality, value, service and on-time delivery that we have built our reputation on for the past 60 years.

From straps and ties to joist hangers and much more, Simpson Strong-Tie® structural connectors increase the strength and safety of timber-frame structures. Each connector is unique to Simpson Strong-Tie and is designed for specific applications without the need to adapt metal plating to suit a connection. Download the Engineered Structural Connectoions flyer.

Steel Frame Connectors

From fully tested and engineered connectors and clips Simpson Strong-Tie® provides comprehensive structural solutions for cold-formed steel construction. From steel-to-steel connections to full-scale lateral solutions and curtain wall connectors, we remain committed to developing new technology that helps to advance the cold-formed steel industry.

Find out how Simpson Strong-Tie timber connectors can help you build the right way every day. Download the Cold-Fromed Steel Construction Connectors Catalogue.

Repair, Protection & Strengthening Systems

Simpson Strong-Tie® has become a trusted manufacturer of chemical, mechanical, direct-fastening, and carbide drill bits and accessories since entering the market in 1994. Now with over 30 years' experience, we continue to expand to provide the most comprehensive product offering to serve infrastructure, commercial, industrial and residential construction markets. These innovative products are the result of more than 40 years of laboratory development, field study and contractor input and have passed the rigorous performance and quality assurance testing you have come to expect from Simpson Strong-Tie. We will continue to expand upon this line of repair, protection and strengthening products and provide our customers with industry leading jobsite, technical and customer support.

Seismic Resilience

Recent earthquakes in New Zealand have starkly revealed the vulnerabilities of our built environment. We need a seismic shift towards safer, stronger structures with improved resilience against earthquakes.

Disasters like earthquakes not only endanger lives, but also cripple communities for extended periods. The short-term loss of utilities and basic amenities can have a significant economic impact. Rebuilding or repairing extensively damaged structures can be a daunting task for individuals and communities alike.

By prioritizing seismic resilience in our buildings, we can create safe havens for our families and minimize the social and economic disruption during recovery. Seismic resilience isn't just about saving lives; it's about protecting the well-being of our entire society.

Seismic Retrofits for Heritage Buildings

Seismic resilience in buildings is addressed under the Building Act for both new and existing structures. The Act's amendments require territorial authorities to conduct seismic assessments of all non-residential and multi-unit residential buildings. This is especially crucial for our heritage buildings, many of which are earthquake-prone and vulnerable.

No matter the element – be it the perimeter masonry walls, the timber frame, or the connections between the roof and walls – Simpson Strong-Tie provides structural products and approved solutions that ensure viable, cost-effective upgrade options for building owners, architects, or seismic design consultants.

- Hurricane Ties provide a positive connection between the truss/rafter and the wall of the structure to resist wind and seismic forces. These ties connect both solid-sawn and engineered timber across a wide range of applications.

- The HTT4 Bracewall Holdown Kit is ideal for retrofit or new construction projects where homeowners and builders require a superior holdown bracket with less joint slip or fastener/connector deformation.

- VT-HP is a high-performance fast cure vinylester resin-based chemical anchor developed for anchoring applications in cracked and non-cracked concrete 20MPa to 50MPa and qualified for use in seismic regions (performance categories C1/C2).

- Titen HD Heavy Duty Screw Anchor is the original high-strength screw anchor for use in cracked and uncracked concrete, as well as uncracked masonry. The Titen HD is BRANZ Appraised No. 983 (2023) for applications related to bottom plate fixings and holdown applications per NZS 3604. It is qualified for static and seismic loading conditions.

Read the article about the Mercury Theatre's Seismic Retrofit Project.

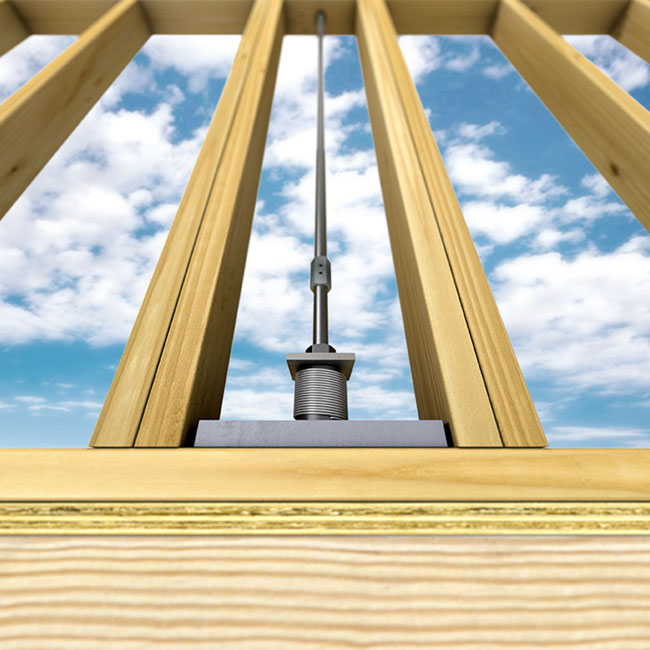

ATS: A Popular Solution for Seismic Resilience

In recent years, there's been a growing trend of constructing hybrid buildings for multi-storey light timber-framed (LTF) structures. These buildings combine lateral load-resisting systems with mass timber walls. According to BRANZ's research and article titled "Timber-based hybrid buildings", such combination bracing systems can significantly benefit the seismic performance of multi-storey LTF buildings.

Simpson Strong-Tie's Strong-Rod Systems have become the go-to choice for continuous rod tiedowns in light-frame, multi-story timber construction. Our Anchor Tiedown System (ATS) tackles shearwall overturning restraint, while the Uplift Restraint System safeguards roofs. These solutions address the specific design challenges faced by multi-story buildings in seismic and high-wind zones.

Learn More: Download the case study to see how ATS enhances MDH design and construction.

Heli-Tie Masonry Wall Reinforcing Systems

The Heli-Tie Brick & Masonry Wall Reinforcing Systems include Helical Stitching Tie and Helical Wall Tie. These solutions are designed for structural and architectural rehabilitation of concrete and masonry.

The Heli‑Tie™ Helical Stitching Tie provides a unique solution to the preservation, restoration or repair of damaged brick and masonry structures. Made of 304 stainless steel, the 6mm diameter tie is installed into the bed joint of damaged or cracked masonry courses using non-shrink repair grout or mortar.

The Heli‑Tie™ Helical Wall Tie is used to anchor building facades to structural members or to stabilise multi-layer brick or masonry walls. The helical design enables the tie to be driven quickly and easily into a pre-drilled pilot hole (or embedded into mortar joints in new construction). Explore our Heli-Tie product range.

FRP Carbon Fibre Reinforcing Systems

Fiber-reinforced polymer (FRP) systems are simply defined as high-strength and lightweight reinforcements created by combining carbon or E-glass fibers with a polymer material. Traditionally, FRP has been used in the civil, aerospace, and automotive industries for applications requiring high strength-to-weight ratios and rigidity.

More recently, the performance characteristics of FRP strengthening have become increasingly popular in construction and retrofit applications, specifically in aging, damaged or overloaded concrete structures. BRANZ has published an article about the extensive research at the University of Auckland on carbon fibre-reinforced polymers (CFRP) helps understand how this material can be used for seismic strengthening, increasing existing buildings’ resilience. Explore how FRP can strengthen your building.

Fiber-reinforced polymer (FRP) strengthening solutions are engineered to address various structural deficiencies or demands in existing buildings:

- Durability issues from poor construction materials

- Inadequate design or construction flaws

- Increased load requirements due to code changes or new uses

- Extending the lifespan of aging infrastructure

- Exceptional or accidental loading

- Seismic retrofitting for earthquake resilience

- Blast mitigation protection

By strengthening existing structures like warehouses and parking garages with FRP, owners can transform previously unusable space into revenue-generating assets.

FRP solutions typically involve a collaborative effort:

- Structural engineers design the solution

- Manufacturers (like Simpson Strong-Tie) supply the materials

- Field-trained contractors perform the installation

Simpson Strong-Tie Composite Strengthening Systems (CSS) provide efficient FRP solutions for the structural reinforcement and strengthening of concrete, masonry and timber structures in need of repair or upgrade. Explore the CFRP product range or Download the CFRP flyer.

Lateral Systems

Little did we know when we introduced our first holdown in 1966 that our product innovations would lead us to solutions that can help hold together five-story buildings during an earthquake or allow builders to more easily retrofit structures and install larger window and door openings in homes. Our offering of lateral-force resisting systems, including Timber Portal Frame System and new Strong-Rod™ Systems, gives designers and engineers added design flexibility in timber-frame construction and the confidence that almost anything is possible.

A History of Testing, Innovation Drives Today's Performance

The Simpson Strong-Tie commitment to product design and testing over the years has resulted in us taking a whole-systems approach to building design. One of the key milestones that launched us down this path was the development of our first factory-built wood shearwall — the Strong-Wall®. Our prefabricated shearwalls improve the quality, consistency and performance of shearwalls in the field.

Strong-Rod™ Systems

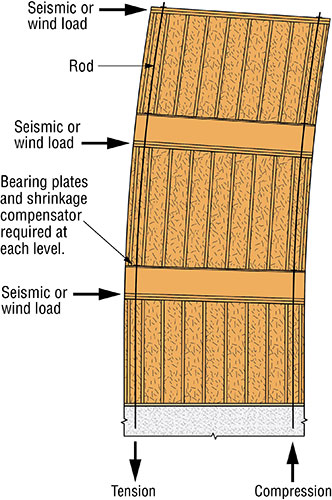

Simpson Strong-Tie Strong-RodTM Systems have become a popular continuous rod tiedown solution for light-frame, multi-story timber construction. Our Anchor Tiedown System for Shearwall Overturning Restraint and our Uplift Restraint System for Roofs address many of the design challenges specifically associated with multi-story buildings that must withstand seismic activity or wind events.

These challenges are complicated, and having a reliable, highly knowledgeable design partner can be critical to keeping projects on time and within budget. No structural connector and lateral systems manufacturer knows light-frame timber construction better than Simpson Strong-Tie, and we have what you need to design your building to resist seismic and wind loads. Code-listed components and systems that come with unmatched testing and design expertise are your formula for success.

Strong‑RodTM ATS solutions address the many factors that must be considered during design to ensure proper performance against shearwall overturning — such as rod elongation, timber shrinkage, construction settling, shrinkage compensating device deflection, incremental loads, bearing plate bending, cumulative tension loads and anchorage.

Why Continuous Rod Tiedown Systems?

|

Seismic and wind events are serious threats to structural integrity and occupant safety. All timber‑framed buildings need to be designed to resist shearwall overturning and roof‑uplift forces. For one‑ and two‑storey structures, connectors (straps, hurricane ties and holdowns) have been the traditional answer. With the growth in mid‑rise, timber‑framed structures, however, rod systems have become an increasingly popular lateral and uplift restraint solution. Multi‑storey structures present complicated design challenges. Frequently, the structures have larger windows and door openings, providing less space for traditional restraint systems. For all these reasons, there is increased need for restraint systems that can meet multi‑storey structural demands without sacrificing installation efficiency or cost considerations. Continuous rod tiedown systems are able to answer these demands by restraining both lateral and uplift loads, while maintaining reasonable costs on material and labour. Instead of using metal connector brackets as in a holdown system, continuous rod tiedown systems consist of a combination of rods, coupler nuts, bearing plates and shrinkage‑compensation devices. These all work together to create a continuous load path to the foundation. |

|||||||||

Tension Forces Resisted by Continuous Rod Tiedown Systems

|

Continuous rod tiedown systems are used to resist two types of tension forces — shearwall‑overturning forces and uplift forces on roofs. One type of tension force is a result of lateral (horizontal) forces due to a wind or seismic event. This force occurs at the end of shearwalls and its magnitude increases at lower levels as it accumulates the tension force from each level or shearwall above. |

||||||||||

Anchor Tiedown System for Shearwall Overturning Restraint

A continuous load path is essential to a building's structural performance. Directing the diaphragm loads from roofs, floors and walls to the foundation in a prescribed continuous path is a widely accepted method to prevent shearwall overturning. The installation of continuous rod systems has grown in popularity with the increase in mid‑rise timber (3‑ to 6‑storey) construction. Specifying a Strong‑Rod™ Anchor Tiedown System (ATS) for shearwall overturning restraint from Simpson Strong‑Tie offers several advantages for Specifiers and installers alike:

- An ATS restraint provides the high load capacities required for mid‑rise timber construction

- System components provide low deflection to help limit shearwall drift

- Steel tension elements of the structural lateral force resisting system

- Our knowledge of rod system performance through years of testing ensures that all system design considerations have been met

Beyond the tension and compression aspects of a continuous rod tiedown system, timber shrinkage must also be addressed. In these types of structures, shrinkage and settlement can cause a gap to develop between the steel nut and bearing plate on the timber bottom or top plate (see photo below), as the shrinkage increases cumulatively up the building and is the greatest at the uppermost floor. This can cause the system not to perform as designed and can add to system deflection. As a result, take‑up devices must be used with most timber structures greater than two stories tall at each level to mitigate any gap creation and therefore ensure optimum system performance. To learn more, go to the ATS product page, or download the Strong-RodTM Catalogue.

Outdoor Accents

Add Beauty and Strength to Your Custom Outdoor Living Structures

With Outdoor Accents®, a complete line of decorative timber connectors and fasteners from Simpson Strong-Tie, you can now bring both design elegance and structural strength to your outdoor living areas. Our Mission Collection® and Avant Collection™ both offer a choice of styles to suit your taste — from ornate and traditional to clean and simple.

This hardware accommodates 90mm and 140mm timber sizes, providing the flexibility you need when designing and building custom outdoor projects such as pergolas, patio covers and other top-supported structures.

Explore Our Outdoor Accents Collections

The Outdoor Accent unique fastening system combines the look of a bolt with the install ease of a screw to make these brackets a breeze to use. No more through bolting, instead the install speed of load rated structural screws into strong and beautiful looking hex head washers gives your structure a timeless appearance with load rated performance.

No matter which collection you choose, all Outdoor Accents connectors and fasteners are rigorously tested for strength and performance. So you'll have a safe, beautiful structure that lasts for years to come.

Mission Collection®

Give a touch of southwestern flair to your outdoor structure with the arched mission-style profile of post bases, straps and angles from the Mission Collection. >> View Collection

Avant Collection™

With straight edges and chamfered corners, the Avant Collection's structural connectors have a clean look that complements nearly every design. >> View Collection

Mass Timber Construction Solutions

For more than 65 years, Simpson Strong-Tie has focused on creating structural products that help people build safer and stronger homes and buildings. A leader in structural systems research and technology, Simpson Strong-Tie is one of the largest suppliers of structural building products in the world. The Simpson Strong-Tie commitment to product development, engineering, testing and training is evident in the consistent quality and delivery of its products and services.

Guaranteed Performance

The fact that we extensively test our connection solutions gives you the reassurance that they will perform in the toughest conditions. Our connector products comply with the AU/NZ timber connector requirements, and our fastener products comply with the European timber fastener requirements. They are suitable for use with AU and NZ sawn timbers, CLT, LVL, and other engineered timber products designed by specific engineering design using AS 1720, NZS AS 1720.1, or NZS 3603, or for prescriptive/conventional connector applications AS 1684 and NZS 3604.

The quality and variety of our product lines gives engineers and builders more freedom to design flexibly, while offering reliable and proven performance. In addition, customers can count on our technical support and a team of experienced field representatives.

The characteristic and design values published within this document have been determined from test and calculation values in accordance with AS 1649, AS 1720, and NZS 3603 for connectors and the fastener characteristic values from BS EN14358 for use with Limit State Design methods. Corresponding deflection limits are published, where appropriate, which indicate the amount of slip in the connection at the design capacity.

Cross-Laminated Timber (CLT)

CLT is growing in popularity as a sustainable and beautiful construction material. Practical too, CLT can be used for walls, floors and ceilings and is well suited to offsite assembly.

CLT has various benefits making it an attractive building material. These benefits include:

- Design flexibility - CLT has many applications. It can be used in walls, roofs or ceilings. The thickness of the panels can easily be increased by adding more layers and the length of the panels can be increased by joining panels together

- Prefabrication - floors or walls made from CLT can be fully manufactured before reaching the construction site, which decreases lead times and could potentially lower overall construction costs

Engineers and Architects are now favouring CLT for its elegance, sustainability and its cosmetic appearance.

Connectors & Fasteners for Mass Timber Construction

At Simpson Strong-Tie we have now released a dedicated range of fasteners and connectors for CLT and Engineered wood mass timber structures. These are purpose designed products, made with the load and design requirements of these building materials specifically in mind. Thought has also been given to the install requirements with fast low torque install designs for our fasteners, and options for collated systems that make connectors quicker to install on site. Download the Mass Timber Construction Catalogue to learn more or check out our Mass Timber Product Range.

Testing the World's Tallest Full Scale Mass Timber Building

It’s Simpson Day at the Natural Hazards Engineering Research Infrastructure (NHERI) TallWood testing site on the UC San Diego campus. The NHERI TallWood project is the tallest full scale building ever to be constructed and tested on an earthquake simulator or shake table. Our Simpson Strong-Tie employees had the opportunity to watch a live in-person seismic test of the 10-storey mass timber building. The NHERI TallWood project aims to investigate the resilience of tall timber buildings by simulating a series of large earthquakes on a full scale, 10-storey mass timber building. This incredible test was made possible by the National Science Foundation (NSF)-funded upgrade of the UC San Diego shake table. It is one of the two largest shake tables in the world and the only large scale earthquake table located outdoors, making it ideal for testing tall buildings.

Simpson Strong-Tie is proud to be a part of this revolutionary project that explores the durability of tall timber buildings in earthquake prone areas. This is an example of the rigorous testing that has gone into the products featured in our local Mass Timber product range.